CO-NELE twin-shaft mixer is mainly used in ready-mixed concrete and environmental protection fields, such as fly ash, sludge, solid waste treatment, soil remediation etc. Streamline mixing arm is adopted to make material mixing more continuous

Twin Shaft Concrete Mixer

Twin shaft concrete mixer adopts Germany Italy European technology used for producing and mixing concrete which is widely used by all over the world. It is

not only applies in common concrete, mix dry-hard concrete, wet concrete,precast concrete but also in high performance concrete.It is applicable for large/

medium-scale construction projects, such as high-speed railway, hydropower construction, large&medium prefabricated factory,airport,road,highway,bridge

and production of high-quality concrete.

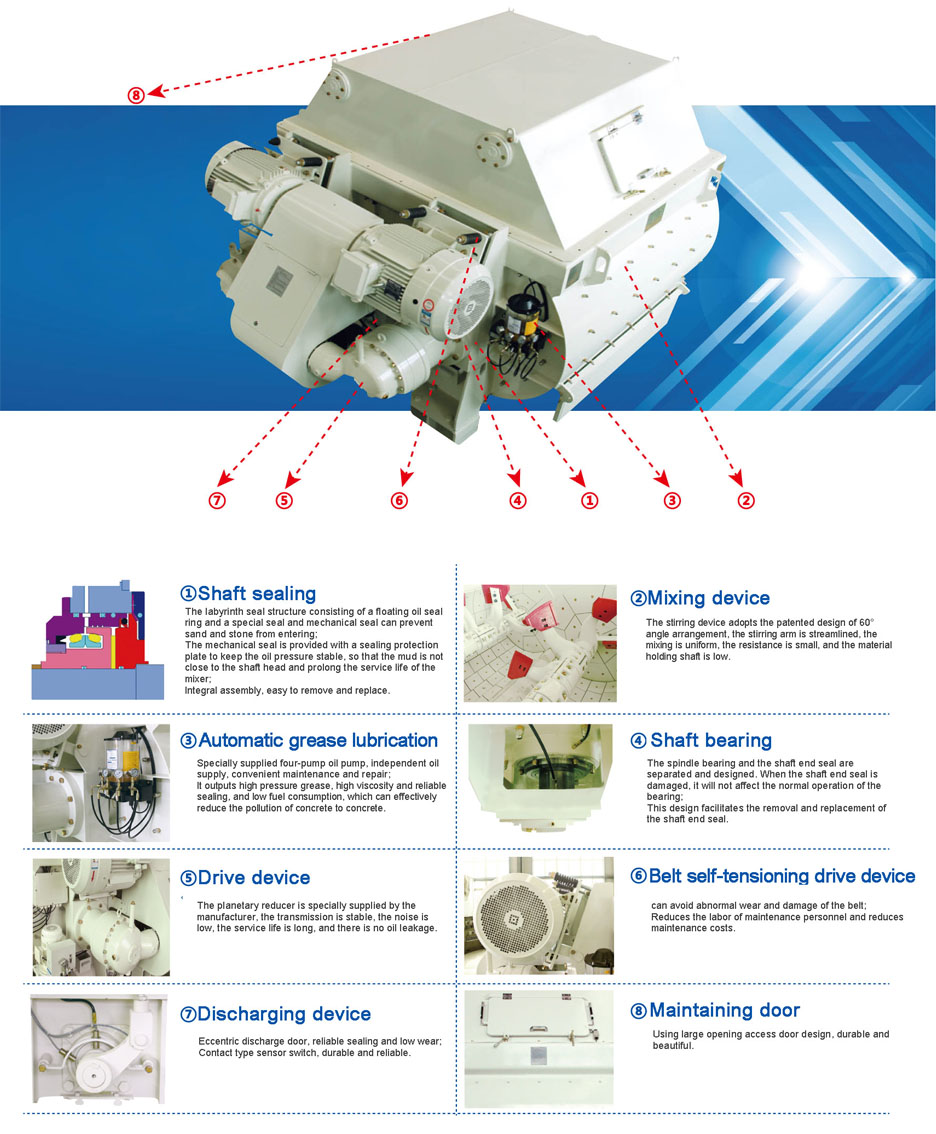

CO-NELE TWIN-SHAFT MIXER ADVANTAGES

1)The shaft end seal is equipped with a floating oil seal ring, a special labyrinth seal structure composed of a seal and a mechanical seal, which has reliable

sealing, high stability and long service life;

2) automatic lubrication system configuration, four independent oil pump, high working pressure, excellent performance;

3) On-mounted motor installation layout, patented belt self-tensioning device to improve transmission efficiency, to avoid excessive wear and damage to

the belt, reduce maintenance costs.

4) The large volume ratio design concept is adopted for the helium cylinder, which can effectively improve the mixing efficiency, prolong the service life of

the shaft end seal,and reduce the probability of material shaft holding;

5) Discharging door adopts eccentric double sealing design to prevent material jamming and leakage, small wear, high sealing efficiency and long-lasting;

6) Stirring device adopts a patented design with an angle of 60°. Flow line casting of the stirring arm results in uniform mixing, low resistance,and low rate of

material holding shaft;

7)Configured with military-grade planetary speed reducers with smooth transmission and high load capacity;

8) Optional original Italian reducer, original German automatic lubrication pump, high pressure cleaning device, temperature and humidity testing system;